In my personal opinion nothing defines the concept of American air superiority as well as the

McDonnell-Douglas (now Boeing) F-15 Eagle. The days of single-role aircraft designed

for a specific purpose are now gone. Now that the emphasis is on budgetary constraints

and finding multiple ways to utilize equipment, we have aircraft designed to try and do all

jobs with a single airframe. Air superiority, ground strike, ground suppression, stealth,

everything rolled into a single airplane. The result is a few aircraft that do everything

marginally well and nothing exceptionally well. The Eagle was the last of the line.

The Eagle flies as few others do. The F-15A (and subsequent "C" version) Air Superiority

variant was designed from the outset as an air superiority fighter, and it's capabilities in

that arena are legendary. The F-15 Eagle has a perfect combat record of 101 victories

and zero defeats in its 30 year history

(Boeing Background).

Over 1,500 F-15's have been produced by McDonnell-Douglas / Boeing.

Take note of the gross aircraft weight and engine thrust numbers in the specifications table

below. The aircraft has a gross weight of 44,500 pounds and two engines providing a total

of 47,660 pounds of thrust. The Eagle was one of the first aircraft to achieve a thrust to

weight ratio greater than 1:1 which also made it one of the first aircraft able to accelerate

going straight up.

Although some variants of the F-15 will still be flying well into this century, the "C" air

superiority variant is destined to be replaced by the F-22 Raptor. There are five primary

versions of the F-15 Eagle:

- F-15A -- Single-seat air superiority variant (replaced by the F-15C)

- F-15B -- Two-seat trainer variant of the F-15A (originally the TF-15A)

- F-15C -- Single-seat air superiority variant (upgraded F-15A)

- F-15D -- Two-seat trainer variant of the F-15C

- F-15E -- Two-seat fighter-bomber or "Strike Eagle".

There are also international variants of the F-15 such as the F-15J and -DJ versions license-built

in Japan by Mitsubishi for use by the Japanese Self Defense Force and the F-15I in use by the

Israeli Air Force. The international variants have the same general configuration as

the US-built F15-C, -D, and -E variants.

On a historical note, the F-15 was the first military aircraft produced by McDonnell-Douglas

Corporation after the merger of McDonnell Aircraft Corporation and Douglas Aircraft on April 28,

1967.

This model is of aircraft number 78-0544. It was assigned to the 44th Tactical Fighter

Squadron, 18th Wing, USAF at Kadena Air Force Base, Okinawa circa 1993.

This Link shows some photographs of 78-0544 as the "44th Fighter Squadron Commander's Jet".

Here Is Another Page on the same site with some detail photographs of 44th Squadron jets. The photographs on the pages,

listed above were taken between 1993 and 1994 even though the copyright is 2000. This information came from a person

who flew F-15's from Kadena during that period and recognized some of the names on the jets.

| Manufacturer: |

Tamiya 1/32 scale McDonnell-Douglas F-15C Eagle

|

|

| Aftermarket: |

Cutting Edge Modelworks 32143 Exhaust Nozzles

Cutting Edge Modelworks 32056 ACES II Ejection Seat

Eduard 32056 PE Set - F-15C Exterior Detail Set

Eduard 32533 F-15 Formation Lights

Eduard 32532 F-15 Interior Set

|

|

| Finishing: |

This model has just been started however it will be finished in the "Mod Eagle" camouflage scheme

adopted for the F-15's in the early 1990's. The colors will be as shown in

These Photographs of 78-0544

as the 44th Fighter Squadron Commander's jet. The "Mod Eagle" colors are supposed to be

FS36176 Dark Grey and FS36251 Medium Grey, however those colors are much, much darker than the

photographs of the jets shown in the page above.

Testors Model Master number 1794 is supposed to correspond to FS36251, which is the lighter of

the two gray tones, and according to the color charts I've seen it is relatively

close to the standard. As far as a color for the actual aircraft it is quite dark. I

haven't come up with a good mix yet, but out of the bottle it is too dark.

Of course, this also depends on how and when you look at the aircraft! Take a look at these

three photos on Airliners.Net. They are all three of

aircraft 78-0496 (44th TFS from Kadena).

First Photo - Taken on March 17, 2005

Second Photo - Taken on March 19, 2005

Third Photo - Taken on March 19, 2005

Same aircraft and two of the photos taken on the same day. The difference in the shade of

the light gray color is obvious though.

|

|

| Build Started: |

July 18, 2005 |

| Build Completed: |

Under Construction |

Note that I have not been following the

instructions exactly in order so the photographs are not in any particular order. I

added them to this page as I finished a section or noticed something that needed to be

added to the page.

|

|

|

|

All images above are links to larger photographs. Click the image to view the larger photo

August 4, 2005 -- I finally got SOMETHING

finished on this model! Not much, mind you, but at least I finished something. I

have several other items started, painted, or otherwise begun but this is the only item that

is more or less finished.

The harness in the front view (photo 2) looks like it has some olive drab paint smeared

on it. It doesn't. There is some dark gray drybrushing on the harness but it

isn't olive drab and it doesn't look like it does in that photo. Trust me, the

real thing looks right.

|

|

|

|

|

All images above are links to larger photographs. Click the image to view the larger photo

August 8, 2005 (Photos revised 09/15/2005) -- Above are the

Cutting Edge Modelworks 32143 Exhaust Nozzles They are painted with Alclad

Stainless Steel and then washed with a black acrylic wash. The insides were sprayed

flat white and then sprayed again with flat black with emphasis on the joints. They

actually look better in real life than the do in the photos because the paint doesn't look

as grainy on the real parts. Keep in mind that the openings are about the size of a

quarter so the photos are much larger than life.

I'm not sure what causes it, but this is the last time I use Alclad primer. I sprayed

the parts with primer, waited 24+ hours and sprayed a second coat. I then waited

another 24+ hours before spraying the Stainless Steel. After three WEEKS they still

feel sticky in places and I've had to be very careful handling them. There is no

reason for this since this primer is a laquer and should dry very quickly. Just

about every time I've used this primer I've had the same problem so I'm going to use

something else from now on.

|

|

|

|

|

All images above are links to larger photographs. Click the image to view the larger photo

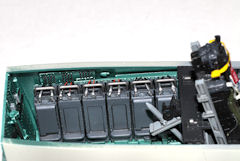

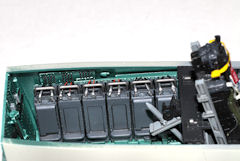

August 9, 2005 -- Above is the main instrument

panel of the

Eduard 32532 F-15 Interior Set partially assembled. As can be seen in photo 1

the panel consists of two layers of PE, one that is the instrument faces and one that is

the outside of the panel. The two are glued together to form the main part of the

panel which is then glued onto the kit panel. All of the detail on the kit panel

must be sanded off prior to assembly so the PE will lay flat on the panel. The

PE set also contains two triangular panels that go on each side as well as some

smaller pieces that I do not have assembled yet. The panel on the right of photo

1 looks like it has some wood-grained areas on it. Those are reflections from

something because those areas are bare metal.

Also as seen in photo 1 there are two screens at the top of the panel that are wrong

if the aircraft does not have the avionics energized. They show light colored

markings on them that would not be visible unless the systems were on. As can be

seen in photo 2 I painted them dark green.

Each individual instrument has received two coats of Future so far to simulate the glass

face of the instruments. I need to add a couple of more coats but when I took the

photos the Future that was there had not dried yet.

There is also a red "Dot" on the lower left side of the panel that is badly out of

register. It appears to be a jettison selector switch and needs to be extended

from the panel somewhat. I haven't fixed it yet but I will before the panel goes

in the cockpit.

Using color photoetch almost feels like cheating. I really enjoy doing cockpits

and it doesn't feel right not doing one. On the other hand the panel just really

looks too good not to use!

Update - 08/12/05 - Photo 3 shows the completed panel. Well, completed except for

the fact that when I looked at the enlarged photo I could see that I still need to work

on the "Red Dot" on the left side of the panel. That control is a raised white

selector switch with a red commit button in the center. I used a very short piece

of 0.040" styrene rod for the selector and put a dot of red paint on the end. I

must have smeared it a bit because it isn't centered on the rod.

|

|

|

|

|

|

|

|

|

|

|

|

Update - 12/31/2009 and 12/04/2011 - Still no work done on this model in over 4 years, but I did take a few more detail photos

of the cockpit

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

All images above are links to larger photographs. Click the image to view the larger photo

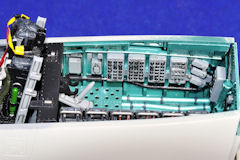

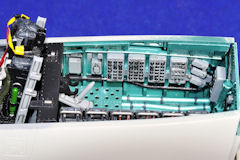

August 15, 2005 -- Here is the completed cockpit

and electronics bay. More or less completed anyway. I noticed in the photographs

a couple of places I need to add some wash and a couple of places that need some paint

touch-up. I also noticed some minor joints between the side panels and the main

panel that need a little filling. Call it 99% complete :)

There is one advantage to taking photos of models and posting them on a web site that I

had not envisioned until I started doing it. When viewed on a computer screen the

photographs are normally much larger than real life. This makes it much easier to

spot minor flaws that I would not otherwise have noticed. When I put photos on this

web site I notice things that I didn't see while building the kit. Things such as

paint flaws, areas of wash that didn't get cleaned up properly or areas that just didn't

get washed. Joints that need a little bit more sanding or filling, decals with

some silvering in them, and so on. The number of minor flaws I can find it photographs

that I never even noticed while building the kit is really amazing.

The instrument panels are

Eduard color photoetch, the ejection seat is

Cutting Edge resin with

Eduard PE belts and harnesses. The electronics bay behind the cockpit is painted

with Xtracolor X159 "F-15 Avionics Bay Metallic Green/Blue" from

Roll Models (note that this paint is oil based

and takes several days to dry). The wiring on top of the TEWS units (photos 8

and 9) was scratch built. Short pieces of solder were drilled out to simulate the

connector to the unit, a piece of thin wire pushed through the solder and into a hole

drilled into the TEWS unit. The wires were then painted orange and black to match

reference photos of the area. The Remove Before Flight flags are

Eduard Color PE (note that they are 1/48 scale flags and not 1/32 scale). The

yellow harness that goes between the pitot tubes on the ACES II ejection seat was scratch

built from foil.

October 20, 2005 -- I haven't done much on this

model in the past month or so. I haven't really put it on hold, I'm just focusing more

of my time on the Trumpeter

F-105D that I am building for a friend. Also, the

Afterburners

are giving me a fit and I haven't decided how to fix them yet.

|

|

Note that I have not been following the instructions exactly in order so these notes

are not in any particular order. I added them to this page as I finished a section

or noticed something that needed to be added to the page.

|

GENERAL ......

|

| |

Many interior areas of the F-15's may be painted in a blue / green metallic

color. Probably the most common place that modelers will run across this color is in

the electronics bay (Bay 5) right behind the cockpit on F-15A and -C models. According

to what I have been able to determine, this color was discontinued between 1979 and

1980. Also, many aircraft that have had depot-level maintenance performed on them since

1980 have had the bays repainted in gloss white. This is not always the case though

because I have read that aircraft stationed at some bases, Kadena AFB for example, did not

have the bays repainted. Keep in mind that this information is based on what I have been

able to find on the internet and may be incorrect. If anyone has any additional comments

or information, I would greatly appreciate

An Email about it.

Update - 01/09/2007 - Thanks to Donivan and his contacts at the USAF for verifying that

Bay 5 is now being upgraded to gloss white during depot-level maintenance.

Here Is An Example of

what the color looks like. The photograph was provided by Dave Masters and has been used

here with his permission.

There are ways to mix this color, but the only exact match that I have been able to find is

Xtracolor X159 "F-15 Avionics Bay Metallic Green/Blue". I have heard that there

are also Gunze-Sangyo and Polly Scale matches but I do not know what they are. I

ordered the Xtracolor paint from Roll Models and

their item number was XT159. I read somewhere that Xtracolor paints are oil based,

and I can believe it because it takes a good while to dry (as in 36-48 hours). To my

eye the Xtracolor X159 paint is a very close match to the actual color and may be seen in

the Construction Photos section above.

|

COCKPIT ......

|

| |

Photos of the completed cockpit and electronics bay can be viewed in the

Construction Photos section above.

I'm using a color photoetch interior for the first time on this model. It is the

Eduard 32532 set The main instrument panel consists of two layers of PE to give

the instruments some depth but the side panels are only a single layer of PE. The

detail that Eduard printed on the panels is excellent and really enhances the cockpit.

One thing I dislike about the main panel are the two screens at the top of the instrument

panel. Both of those screens are printed in a somewhat medium green color with light

green lines shown on them. For an aircraft in flight this would be fine, but for a

parked aircraft the avionics would be off and the screens would be dark green with no

lines showing on them. This is not a big issue since all that is necessary is to

paint over the screens with some relatively dark green paint.

Also take note of the fact that the Eduard color PE panel is a "Pre-MSIP" (Multi-Stage

Improvement Program) panel. The MSIP replaced most of the avionics and weapons systems

in the F-15 with vastly updated systems. Keep in mind that many of the F-15's have been

in service for over 20 years and there have been quantum leaps in electronics over the

intervening two decades. According to

This Page on the Robbins AFB web site, "All F-15A/B/C/D aircraft produced before 84-001

will receive the MSIP retrofit at the F-15 depot. This upgrade added a MPCD

(Multi-Purpose Color Display) to the weapons panel on the left side of the main

instrument panel which is not on the Eduard panel. In addition, the MSIP upgrade gave

the F-15 the ability to carry AMRAAM and did not have the LAU-128 launch rails, so any

Pre-MSIP aircraft could not carry AIM-120's. Also, they did not have the round

antenna on the right tail cone, so be sure to use the pointed one that Tamiya provides. Thanks

to my buddy Darren for this information.

For photographs of the completed main instrument panel see the

Construction Photos above.

If you decide to use the

Eduard 32532 Interior Set there is one minor detail that you will need to be aware

of. There are three panels that replace the main instrument panel and both side

panels. You will have to sand the existing instruments off of the kit panels, but

this is a minor chore and only takes a few minutes.

The problem is that the left side panel requires that you cut the throttle quadrant off

and reuse it. Since the throttles are on the side of the panel closest to the seat

it makes it difficult to cut them out without the gap showing in the edge of the panel. It

is probably possible to score around the throttles with a hobby knife and leave the edge

of the kit panel in place, but there is not much room. I just used a saw to cut the

throttles out. This did leave a gap in the edge of the panel, but the panel at that

area is 0.040" thick so I used two pieces of 0.020" styrene (because I had some on hand)

to fill the edge back in. It only took a few minutes to do.

If you decide to use the

Eduard 32056 PE Set - F-15C Exterior Detail Set it does include some pieces for the cockpit,

specifically belts and harnesses. One piece that the instructions indicate should be

installed is incorrect. The very first section indicates that a center ejection

pull handle (part no. 13) should be installed on the ejection seat. While this is

correct for the ACES II in an F-16 it is NOT correct for the F-15 seat.

Here Is A Link to the ACES II seat of an F-15 on

The Ejection Site and Here Is A Link

to an ACES II of an F-16 on the same site. Notice that while the F-16 seat does have

the center pull the F-15 seat does not. The description of the seat on the F-16 page

specifically mentions that the seat for the F-16 and F-22 differ from other variants in that

they use a center pull. If you see a photo of an F-15 with a center-pull ejection seat

it is an older style Escapac ejection seat.

If you decide to use the

Cutting Edge Ejection Seat be aware that it does not have seat rails

on it. The kit rails are molded to the seats, but they are not difficult to

cut off and add to the resin seats.

Additionally, there are two brackets on the bottom of the Tamiya seat that you will need to

use. Without it the Cutting Edge seat will sit too low. There are two pieces,

one on each side of the seat that fit into slots in the cockpit floor. Just cut

them off the kit seat, make sure they are the same height, and glue them into the cockpit

floor using the slots provided. When you are ready to install the Cutting Edge seat

just glue it to the tops of the brackets.

Even though the F-15C is a single-seater Tamiya provides two ejection seats. I guess

it's easier for them to have one parts bag that works on the F-15C and F-15E even though

there is an extra seat for the "C".

If you decide to use the

Eduard 32532 Interior Set the instructions show part number 17 (lower left of page 2)

in the wrong location. This part appears to be three placards connected as a single

unit. The instructions show it mounted to the edge of the cockpit beneath the

windscreen. As can be seen in

This Photograph they are plainly visible (well, two of them are "Plainly" visible,

the third is not as easily seen) right in front of the rear edge of the windscreen

ABOVE the rim of the cockpit on the framing of the windscreen.

|

ELECTRONICS BAY ......

|

| |

Photos of the completed cockpit and electronics bay can be viewed in the

Construction Photos section above.

The electronics bay immediately behind the cockpit is "Bay 5". In the middle of the

bay floor there is a large round stud sticking up that a screw goes through to join this

part with the nose gear bay below. There is nothing to cover this stud except the

screw head itself. There is nothing similar to this in the real bay and it would

probably be best to grind it out and putty the hole. The problem with this is that

there are some cables and cable trays that pass through it that would have to be

reproduced. I chose to leave it and filled the screw head (it is a small Phillips

screw) with gap filling Zap and then painted it the same color as the bay.

The Electronics Bay is frequently painted in the metallic blue / green color as mentioned

in This Comment shown above. If the aircraft was manufactured

after 1979 or has been upgraded the bay might have been painted gloss white.

|

ENGINES ......

|

| |

I decided to use the

Cutting Edge exhaust nozzles instead of the kit parts. According to the information

provided, the Tamiya nozzles are approximately 1/4" longer than they should be. Photos

of the completed cans can be seen in the Construction Photos above.

Based on the photographs I have found on the internet the exhausts of the F-15 range in

color from a dark metallic "Burnt Iron" color to a bright "Stainless Steel" color. I

suspect this has something to do with the age of the engines and how they have been treated,

but the bottom line is that it appears pretty much any color would be correct in some

respect. I used Alclad Stainless Steel for mine and then gave them a black acrylic wash.

Also, the insides of the augmenters (or "Cans") on the engines are ceramic coated so they

are white in many places. As would be expected there are numerous areas of black soot,

but the background is white or a very light ash gray, not metallic.

Finally, of all the photos I have looked at that show the "Turkey Featherless" exhausts

of the F-15, none of them show any heat discoloration. I took some photographs of

an F-15A with early engines that have "Turkey Feathers" and they show distinct

discoloration from heat. That can be seen in

This Photograph. However, as can be seen in the exhaust photographs on

This Page taken

by Zoltan Pocza there is no evidence of heat discoloration.

The intake trunks and afterburner sections are tough. That isn't unusual on jet

models though. As usual both of these consist of an upper and lower half that are

glued together to form the intakes and burners.

The intake trunks just take some patience as can be seen in the photos below. All of

the images are links to larger photographs. Click the image to view the larger photo.

Photo 1 shows the left intake after being glued with Tenax and a coat of Mr. Surfacer 1000

applied. You can easily see the seam starting at the

upper corner, angling down, and then going all the way to the back end. Photo 2 shows

the right side of the assembly after the seam was removed. Before filling and sanding

it looked the same as the mess on the left side. It took several hours of filling,

sanding, and priming to see if the seam was gone, and then repeating the process until it

actually was. It takes some work but here is the proof that the guys who say it can't

be done are dead wrong.

Photo 3 shows the outside of the intake trunks. You can see some strips of styrene

down the sides that aren't included in the kit. I normally put those on the outside

because after putting a lot of work into getting seams out I really don't want the joint

to split back open. I sometimes have to sand them down in places to fit into the

fuselage but the really do help strengthen that joint.

The afterburner sections are just plain evil and I haven't done them yet. Photos of

the parts are shown below.

As can be seen in photos 4 and 5 the inside of the afterburners is ribbed. Photo

6 shows the seam that is going to be present when the two halves are assembled. Any

sanding that is done to remove the seam is going to ruin the ribs. Even using a

"Welding" type of glue such as Tenax that creates a bead of melted plastic is going to be

difficult to fix. I've gotten some good advice on how to resolve the problem and

when I get them assembled I'll post some photos here and information on how I did it.

|

ORDNANCE ......

|

| |

I haven't done a lot on the ordnance yet. I got tired of working on other things

and decided to play with the missiles just for a change of pace.

AIM-9L -- The Sidewinders are in pretty decent shape (compared to those in some

other models I could mention they are in great shape!). Each missile is composed of

5 parts; the main missile body with two forward and aft fins molded on, a single piece that

forms the other two aft fins, two individual forward fins, and an end cap. There are

four ejection pin marks on the top (I think it's the top) of the main missile body. These

pin marks may or may not be visible once the missiles are mounted. I don't think they

will be but I decided to fill them anyway. There are also some minor seams along the

sides where the mold halves joined, but these are easily sanded off. The end cap has

a minor ejector pin mark in it that needs to be removed.

I found an excellent source on the internet for AIM-9 information. The site is

Jim Ball's Scale

Library of Missile Data and his page pertaining to the AIM-9 is at

This Link

Most of the photos appear to be of an AIM-9D but they still provide some excellent

reference for the modeler.

AIM-7 -- I haven't even touched the Sparrows yet so I don't know how they will stack up.

|

|

For anyone who might be interested, here is how my time breaks down so far. Keep in mind that I don't

punch a time clock or anything like that. After I work on it a while I write down approximately how

much time I spent on it and what I did. It's relatively close, but not exact by any means.

| General Assembly |

29.5 hr |

|

5% Complete |

| Painting (excluding cockpit, engines, stores, & landing gear) |

14.0 hr |

|

2% Complete |

| Decals and Panel Line Wash |

0.0 hr |

|

0% Complete |

| Engine Exhausts (including painting) |

17.0 hr |

|

85% Complete |

| Intake Trunks (including painting) |

17.5 hr |

|

100% Complete |

| Cockpit & Electronics Bay (including painting) |

51.5 hr |

|

100% Complete |

| Stores (including painting) |

0.0 hr |

|

0% Complete |

| Landing Gear (including painting) |

10.0 hr |

|

33% Complete |

| TOTAL TIME THROUGH 09/15/05 |

139.5 hr |

|

15% Complete |

|

| Aircraft Name: |

McDonnell-Douglas F-15C-23-MC Eagle |

| Year of Construction: | 1978 |

| Aircraft Category: | Air Superiority Fighter |

| Wing Span: | 42.8' |

| Overall Length: | 63.8' |

| Height: | 18.5' |

| Gross Weight: | 44,500 lbs |

| Engine: | Two F100-PW-220 Pratt and Whitney turbofan engines with afterburning |

| Thrust: | 14,670 (dry) / 23,830 (afterburning) pounds each |

| Speed: | Mach 2.5 |

| Range: | 3,450 mi (ferry range with internal fuel, 2 FAST pack conformal fuel tanks, and 3 external drop tanks) |

| Ceiling: | 65,000 ft |

| Date of First Flight: | July 27, 1972 |

| Date Deployed: | November, 1974 |

| REFERENCES AND MY THANKS TO ... |

|